MILITARY INTEGRATED LOGISTICS MAINTENANCE MANAGEMENT

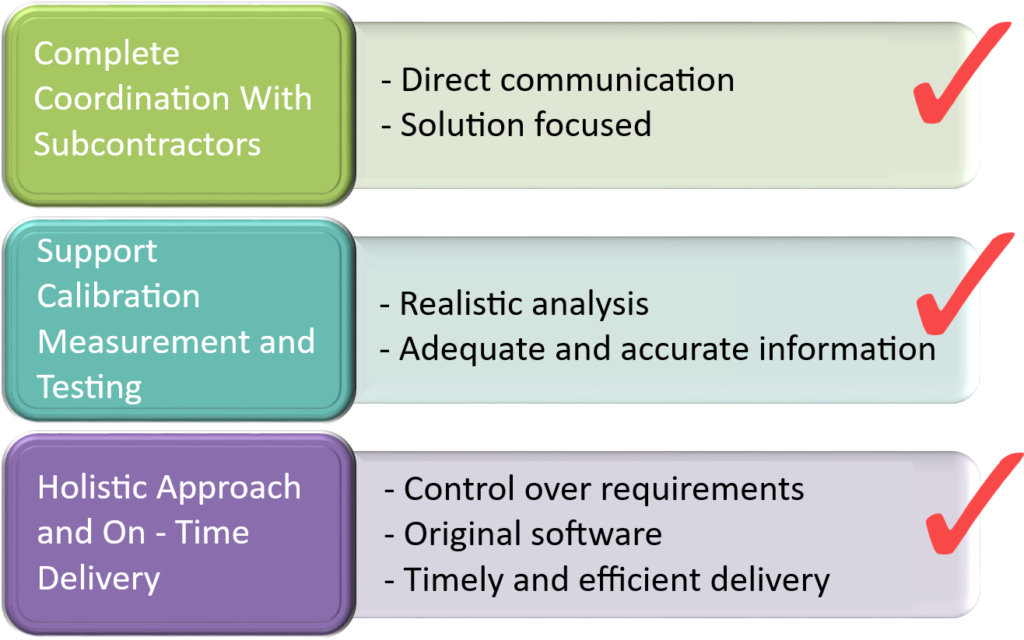

It is the responsibility of developing a maintenance program that can support a system and then planning the detailed maintenance activities required. GMKA will be able to develop maintenance plans based on the data provided by subcontractors.

After the logistic analysis, GMKA will be able to deliver the planned maintenance system related to the system and its subsystems, and the printed delivery of the maintenance cards required for this system.

After analyses,

• Consumables,

• Hand tools,

• Special tools and equipment,

which are necessary for maintenance and repairs, can be identified.

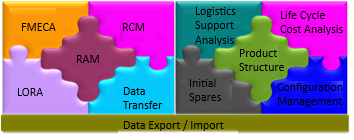

• MAINTENANCE MANAGEMENT AND PLANNING

Physical Breakdown (Bill of Material-BOM) information of all systems, failure and troubleshooting methods, “Preventive and Corrective Maintenance” information and documents, determination of maintenance centers and maintenance planning and preparation of related documents.

• PREPARATION OF MATERIAL AND STAFF DOCUMENTS

Determination of the systems and devices in the platform configuration and the spare parts, test and hand tools, inventory material staff required for their operation and production of relevant documents.

• IDENTIFICATION OF INITIAL SPARES

Determining the initial spares required during the delivery of the platform and system to the user.

PERFORMANCE BASED LOGISTICS (PBL)

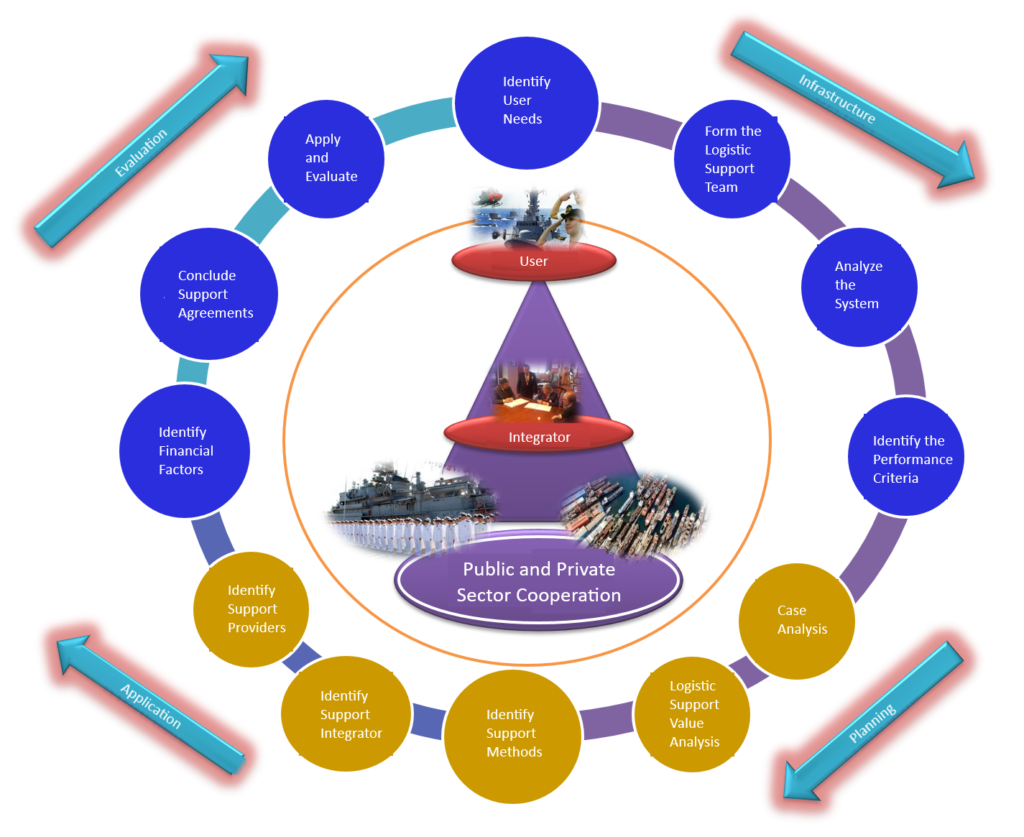

OUR GENERAL PBL APPROACH

Instead of supplying maintenance, training, data, documents and spare parts as part of traditional procurement by entering into long-term and separate logistics contracts (agreements), it is the approach to supply the specified performance criteria (reliability, operational readiness, cost, logistics trace, logistics time, etc.) with the most appropriate public-private cooperation.

• WHAT IS PERFORMANCE BASED LOGISTICS?

Raising awareness for culture change, determining the real needs of the end user, purchasing performance from the supplier rather than a single product, establishing long-term relationships, mutual risk sharing, taking up a program management perspective, each unit involved in the process focusing its own core competencies, communicating to the supplier not “how” but “what” is desired, focusing on life cycle, strategic and smart procurement, and creating added value.

• INTEGRATION OF LOGISTICS DISCIPLINES

Maintenance, spare parts, technical documentation, special test and measurement tools, software, hardware, personnel, training, infrastructure, packaging-handling-transportation, configuration

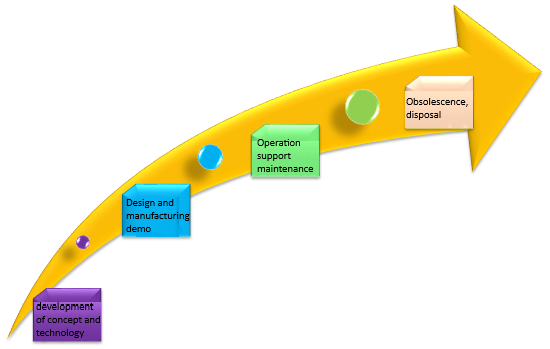

• OBSOLESCENCE MANAGEMENT

Proactive approach, awareness, preparation, design, evaluation, analysis, implementation

• MAINTENANCE MANAGEMENT

Improvement in cost, effectiveness, flexibility, speed, technical and logistical times

Procurement

-Contract management

-Determining support needs

-Support design (integration)

-Budget management

-LDA

-CRM

Service Introduction

-Contract management

-Logistics database

-Technical documentation

-Initial spare determination

-Maintenance plans

-Spare part plans

-Personnel plans

-Infrastructure plans

-Test and evaluation

-Financial management

-CRM

Management

-Contract management

-Obsolescence management

-Configuration management

-Logistics support analysis

-Document management

-Maintenance management

-Inventory management

-Spare parts management

-Personnel management

-Training

-Infrastructure management

-Budget management

-Financial management

-Warranty management

-CRM

OUR PBL SERVICE SCOPE AND ADVANTAGES

MAINTENANCE PROJECT IN PBL

• It is designed as a concrete step within the scope of PBL.

• It will be more effective and efficient with the maintenance of complex systems and implementation of private sector practices.

• A fast and flexible maintenance system will be attained.

MAINTENANCE SUPPORT-OUR CAPABILITIES

• Gathering and analyzing the data of the device and material information applied, and presenting decision support information for future maintenance and repairs,

• Collecting and analyzing data on failure and repair activities, keeping failure statistics, modification and disposal, helping decision support ,

• Monitoring and reporting of changes within the framework of configuration and maintenance activities,

• Making document changes in maintenance and repair activities and possible modifications and configuration changes.

GMKA AS PRODUCT SUPPORT INTEGRATOR;

GMKA is ready to serve as a support provider with its competent human resources, experience and knowledge in analysis and decision support in matters such as:

• Providing consultancy services during the design phase of the envisaged structure,

• Preparing the contract,

• Operation of the supply processes within the scope of sustainment and maintenance,

• Preparation of the database,

• Information system creation and adaptation and integration of related software (ELD, IMS, stock, purchasing, accounting…)